cyclone de lavage à sec pour le sable

Station de lavage avec équipée avec hydro-cyclone et Installation de clarification des eaux et déshydratation des boues équipée avec FILTRES PRESSES A BANDE ... pour en sortir du sable sec et recycler l'eau pour la réutiliser ...

Consulter un spécialiste

Cyclone de lavage sable - Devis sur Techni-Contact

Cyclone de lavage sable. Jusqu'à 120 tph de production de sable. Code fiche produit :341923. . Pour le traitement du sable ou tout autre matériau concassé, nous vous

Consulter un spécialiste

Installation de lavage de sable avec hydro-cyclone, sable 250

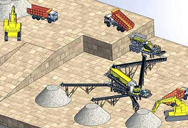

Les groupes de récupération de sable avec hydro-cyclones ont étés projetés et réalisés pour le lavage, le criblage, le séchage et la séparation de sable présent dans les eaux

Consulter un spécialiste

Hydrocyclones SOLHYDROC SOLHYDROC

Les hydrocyclones peuvent être utilisés pour différents types de matériaux, tels que le sable, le gravier, les minéraux et les boues. Ils peuvent également être utilisés pour le

Consulter un spécialiste

Alquezar - Hydrocyclones ou équipement de récupération de sable.

Les équipements récupérateurs de sable ou hydro-cyclones sont conçus pour le lavage et la récupération des sables dissous dans l’eau provenant du lavage des granulats. Dans

Consulter un spécialiste

Valorisation et lavage du sable - MS

MS possède une forte expertise en valorisation et lavage du sable. Nos méthodes de lavage du sable on fait leur preuves dans les différents chantiers que nous avons traités. Nos

Consulter un spécialiste

Cyclone de lavage agrégats - Machines de lavage industriel

Les équipements de lavage sable sont basés sur le principe de filtrer le sable à l’aide d’un hydro-cyclone, le système en question est composé d’un bassin qui permet de collecter

Consulter un spécialiste

LAVAGE DES SABLES DE FILTRAGE - CDE CDE

L'équipement CDE conçu pour le lavage des sables de filtrage assure un approvisionnement continu en sable de filtrage propre et sec, de granulométrie uniforme et qui répond à

Consulter un spécialiste

Installations et équipement de lavage de sable et granulats

Nous travaillons avec les plus grands producteurs de sable et de granulats au monde pour concevoir et fournir des usines de traitement par voie humide qui: Maximisent la durée

Consulter un spécialiste

Guide complet des symboles de lavage : comprendre les

2024年4月3日 En l'absence de chiffres indiquant une température spécifique, cela peut être interprété comme une indication que le lavage à une température normale est acceptable. Le symbole de lavage avec une barre sous le seau indique que le vêtement ne doit pas être lavé. En d'autres termes, il s'agit d'une indication pour le lavage à sec ...

Consulter un spécialiste

cyclone de lavage à sec pour sable

Cyclone de lavage de sable sec - qbsystems . Cyclone de lavage agrégats - Nettoyage - Techni-Contact. Les équipements de lavage sable sont basés sur le principe de filtrer le sable à l'aide d'un hydro-cyclone, le système en question est composé d'un bassin qui permet de collecter le sable et l'eau, une pompe pour immerger les agrégats dans le

Consulter un spécialiste

Comprendre le fonctionnement du nettoyage à sec - Blog

Le nettoyage proprement dit. Comme son nom l’indique, le nettoyage à sec est une technique de lavage sans contact avec l’eau. Elle utilise plutôt du solvant organique comme du perchloroéthylène, un produit qui élimine parfaitement les graisses et respecte les apprêts d’ennoblissement des textiles. Le nettoyage s’effectue dans une ...

Consulter un spécialiste

Le nettoyage à sec pour un lavage sans risque

2015年3月13日 Le nettoyage à sec s'adresse principalement aux matières telles que le daim, le cuir ou les plumes. D'une manière générale, ce type de nettoyage est à privilégier pour les vêtements qui ne supportent pas un passage à la machine. D'autres matières fragiles telles que la soie, la laine ou le coton peuvent être lavés délicatement à ...

Consulter un spécialiste

cyclone de lavage à sec pour sable

Accueil >> cyclone de lavage à sec pour sable . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. ... concasseurs mobiles et écrans pour le minerai de fer . afrique concasseur fabricant de l installation du sud . concasseur primaire barytine a vendre .

Consulter un spécialiste

Cyclone de lavage a sec du sable - adifix

cyclone de lavage au sable sec. cyclone de lavage à sec pour le sable. Unité de lavage de sable 60 à 100 T/h 65000 EUR . consulter en ligne; Cyclone de lavage sable - Devis sur Techni-Contact. Pour le traitement du sable ou tout autre matériau concassé, nous vous proposons notre cyclone de lavage sable. Une solution parfaite pour le ...

Consulter un spécialiste

La Swash, machine de nettoyage à sec pour le particulier :

L'appareil électroménager va appliquer un lavage à sec sur le vêtement, ce qui va le "rafraîchir" (donc supprimer les éventuelles odeurs) mais aussi enlever les plis qui auraient pu se former. L'idée est d'espacer les séances de lavage à la machine et de repassage, qui ont tendance à abîmer les vêtements.

Consulter un spécialiste

Installation de lavage de sable avec hydro-cyclone, sable 250

Installation realisee en U.A.E. Installations de lavage. Les phases de lavage et nettoyage permettent d’éliminer des agrégats les impuretés comme sable, argile ou feuilles, agissant sur la qualité finale du produit. MAITEK dispose également d’une grande variété d’équipements pour le l avage des agrégats et la récupération du sable.

Consulter un spécialiste

Cyclone de lavage sable - Devis sur Techni-Contact

Pour le traitement du sable ou tout autre matériau concassé, nous vous proposons notre cyclone de lavage sable. Une solution parfaite pour le lavage, le criblage et le drainage sans aucune perte de petite portions, et ainsi obtenir un produit final de qualité. Grâce à cette technique, une excellente granulométrie est obtenue à la sortie et vous pouvez avoir

Consulter un spécialiste

Comment nettoyer un vêtement à sec ? Lemahieu

2020年9月29日 Pulvérisez le produit nettoyant sur la ou les tâches de votre vêtement. Placez votre vêtement à l’intérieur du sac de nettoyage à sec, puis ajoutez une lingette. Programmez un cycle doux à basse température dans votre sèche-linge. Enfin, accrochez votre vêtement sur un cintre. Ainsi, votre vêtement ne sera pas froissé.

Consulter un spécialiste

Le nettoyage à sec chez soi - Koolnet

2019年1月21日 Après le lavage, pensez à immédiatement les essorer sur un cintre. Normalement si votre linge passe en machine et résiste aux secousses, vous devriez trouver le pictogramme : Suspendre pour

Consulter un spécialiste

Station de lavage avec équipée avec hydro-cyclone et Installation de ...

Station de lavage avec équipée avec hydro-cyclone et Installation de clarification des eaux et déshydratation des boues équipée avec FILTRES PRESSES A BANDE ... pour en sortir du sable sec et recycler l’eau pour la réutiliser dans le ... Les débourbeurs à tambour sont appropriés pour le lavage de matériaux très sales tandis que les ...

Consulter un spécialiste

Filtre cyclone séparateur de sable hydrocyclone 1" 1/2 M

251,64 €. Le filtre à sable hydrocyclone AGREN élimine jusqu'à 90% du sable et des particules supérieures à 75 μ présents dans l'eau de votre système. Débit hydrocyclone : 12,6 m³/h ; 3,5 l/s. Connexions : 1" 1/2 mâle fileté. Bac de récupération de sable : filetage mâle 1". Pression de service maximale : 10 bars.

Consulter un spécialiste

Cyclone de lavage à sec du sable - mobilnemieszkanie

Cyclone de lavage a sec du sable. Cyclone de lavage sable : Devis sur Techni-ContactCyclone de lavage sable Jusqu'à 120 tph de production de sable Code fiche produit :341923 Demander un prix Pour le traitement du sable ou tout autre Cyclone de lavage à sec du. Consulter un spécialiste Cyclone de lavage a sec du sable

Consulter un spécialiste

Nettoyage à sec : la méthode douce pour laver votre linge délicat - La ...

2024年7月15日 Le nettoyage à sec : une méthode douce pour laver son linge. N’essayez même pas d’essayer chez vous ! Le nettoyage à sec est un procédé de lavage du linge en machine, réalisé exclusivement par un professionnel. Le principe ? Contrairement à ce que son nom laisse penser, le nettoyage à sec utilise du liquide !

Consulter un spécialiste

Comment faire un lavage à sec en machine - Le Vêtement

2021年6月30日 Nettoyage à sec aux cristaux de soude. Préparez une solution avec un litre d’eau chaude et 2 cuillères à soupe de cristaux de soude; Appliquer un chiffon humide pour nettoyer à plat; Trempez la baignoire avec la solution et faites-le bien; Essuyer avec des gants, insister sur place ;

Consulter un spécialiste

Peut-on nettoyer ses vêtements à sec à la maison ? Guide

2024年7月13日 5. Lavez votre linge de maison en lin à l’eau froide. Dans une cuve remplie d’eau froide, ajoutez un peu de lessive douce et lavez à la main votre linge de maison. Une fois le lavage terminé, vous devez presser le linge et le sécher à l’air. Si vous ne le faites pas, il risque de froisser.

Consulter un spécialiste

Lavage de ma voiture : 5 astuces pour une carrosserie parfaite

2020年7月10日 Découvrez notre guide du conducteur pour les automobilistes, avec notre volet sur les 5 astuces de lavage à la main pour une carrosserie parfaite sur votre voiture.

Consulter un spécialiste

LES PRINCIPES DU FONCTIONNEMENT DES

Les hydrocyclones peuvent être considérés comme des systèmes de filtration différents des autres systèmes de filtration physique les plus courants, tels que la filtration sur lit (filtration en profondeur à faible vitesse), à anneaux ou à tamis (filtration de surface).. Les hydrocyclones également connus sous le nom de cyclones, sont des équipements

Consulter un spécialiste