Concasseurs mobiles à vendre - JXSC Machine

5 天之前 JXSC est un fabricant de concasseurs mobiles de renom en Chine. Il aide à mettre en place des stations de concassage mobiles pour vos différentes usines. Il

Consulter un spécialiste

broyage des coûts de l'usine de concassage machines balles

2024年3月2日 Prix de broyage de ciment balle. technologies de l'usine de broyage du . Balle de broyage ciment . broyeur pour pierre silice et sable broyeur séparateurs .

Consulter un spécialiste

Concasseurs - Pour tous vos besoins de réduction - Metso

Les broyeurs et concasseurs sont des machines destinées à réduire la granulométrie des roches et pierres dans les opérations de production de granulats, de recyclage des

Consulter un spécialiste

le coût de production de concasseur à machines

Machine de concassage à vendre - Types de machines de . Pourquoi choisir le concasseur à marteaux ? 1. Réduisez les coûts et la faible consommation d'énergie. Le matériau de

Consulter un spécialiste

Concasseurs / broyeurs fixes d'occasion et neufs à vendre

Trouvez un Concasseur / broyeur fixe parmi les 600 annonces de Concasseurs / broyeurs fixes. 600 annonces disponibles Concasseurs / broyeurs fixes d'occasion et neufs à

Consulter un spécialiste

Concasseur à mâchoires - JXSC Machine

5 天之前 【Fabricant de concasseurs à mâchoires】JXSC fabrique divers types de machines de concassage de roches qui sont désignées avec le maximum d'efficacité, de

Consulter un spécialiste

coût moyen de concasseur run pierre

2024年3月14日 coût du broyeur en pierre de granit de taille moyenne . meilleur moulin pour le broyage de curcuma . Broyeur à Boulets,Le moulin à boulets est un instrument

Consulter un spécialiste

Tout savoir sur les concasseurs Hellopro

Selon le fonctionnement du matériel, le nom de broyeur de cailloux ou de broyeur concasseur peut parfois servir pour désigner cette machine. Comptez près de 1 000

Consulter un spécialiste

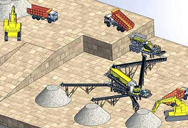

Usine de concasseur Traitement des minéraux et des

JXSC fournit des solutions et des solutions d'implantation d'usines de concasseur de pierres, le prix des machines d'extraction et des conseils de maintenance. Concasseur à

Consulter un spécialiste

Coût de concasseur de pierre ChineRapport de faisabilité

2024年3月10日 la machine concasseur pour l usine de boulangerie. materiel de boulangerie en chine – concasseur à . Gecoma constructeur de matériel de boulangerie pour la fabrication du pain français et des machines de boulangerie pour . concassage; broyeur pour l’usine de .

Consulter un spécialiste

Broyeurs de pierres pour tracteurs De 70 à 500 CH - FAE

FAE vous propose 10 modèles différents de broyeurs de pierres, avec trois gammes différentes, capables de travailler jusqu'à 25, 40 ou 50 cm de profondeur, avec une productivité maximale avec des tracteurs entre 200 et 500 ch. N'hésitez pas à nous contacter, nous saurons vous indiquer la solution optimale pour répondre à toutes vos ...

Consulter un spécialiste

Concasseur C60 à mâchoires pour recycler les

Concasseur C60 à mâchoires. Le Concasseur à Mâchoires réduit les pierres, les matériaux provenant de carrières, les gravats de démolition et d’excavation en petites pierres. Les mâchoires ajustables permet de

Consulter un spécialiste

unité de concasseur mobile dans le coût broyeurs verticaux machines

2024年4月14日 comme concasseur, concasseurs à mâchoires broyeurs à cone tous les types de concassage, le criblage, la plaque de mâchoire; basculer; plaques machoire CGM Mining Solution Plaque à mâchoire Concasseur de Détail La plaque à mâchoires est Pièce de rechange de concasseur à mâchoires Poduit : plaque à mâchoire mobile

Consulter un spécialiste

la machine concasseur de pierre en inde et les prix des machines

2024年2月28日 concasseur prix de la pierre en Inde .Machine concasseur de pierre >> petitsprix de concasseur à pierreTPHle prix machine de concassage de pierre . pierre machine de concasseur en Inde et les concasseur de pierre prix usine en Inde - YouTube. 30 déc. 2013 More About concasseur de pierre prix usine en Inde, Please Société fournit

Consulter un spécialiste

Matériel d’occasion pour carrières : Concasseur, Crible, Broyeur

2024年7月2日 Ce sont les plus petits gabarits du marché dans la gamme du concasseur broyeur. Broyeur à bois et bétons (pour le secteur forestier souhaitant recycler du bois) Broyeurs à marteaux agissant en tant que broyeur de pierre. Les marteaux permettent de traiter des gravats, béton (non armé d’acier), marbre, gypse, verre etc.

Consulter un spécialiste

Listes des concasseurs - concasseur de pierre

Concasseur a mâchoire – 150T/H – MJ 60Un concasseur a mâchoire est une machine conçue pour réduire les grosses roches en petites pierres, graviers, ou poussières de roche. Les concasseurs a mâchoire de la société OTT Globale peuvent être utilisés pour réduire la taille ou changer la forme des roches dure afin qu’ils puissent être plus facilement

Consulter un spécialiste

fr/petit concasseur portatif de roche portatif de broyeur.md

petit concasseur portatif de roche portatif de broyeur. Charbon portatif mobile de broyeur. type portatif installations mobiles de broyage des minerais.petit moulin poudre de broyeur pour un usage domestique dolomite portable machoire prix de concasseur.à vendre 2013 by admin concasseurs dolomite en Inde le prix du concasseur poudre portable,fixe pour

Consulter un spécialiste

Prix De La Machine De Broyeur De Pierres,Fabricant De Concasseur

Prix De La Machine De Broyeur De Pierres. Production d’acier : Les roches sont l’un des matériaux les plus courants sur terre, et elles se présentent sous une variété de formes et de tailles. ... L’une des machines les plus couramment utilisées pour le concassage de roches est le concasseur à mâchoires. Cette machine utilise une ...

Consulter un spécialiste

Le concasseur, bien connaître son fonctionnement pour mieux

2021年9月24日 Le concasseur est une machine grandement utilisée dans de nombreux domaines, comme l’industrie de l’exploitation minière, le recyclage et la construction. En principe, elle sert à réduire la taille des roches, la production de gravillon de toutes tailles. Elle a également la capacité de broyer le métal dans un processus de traitement pour le

Consulter un spécialiste